What Are Active and Passive Fall Protection Controls?

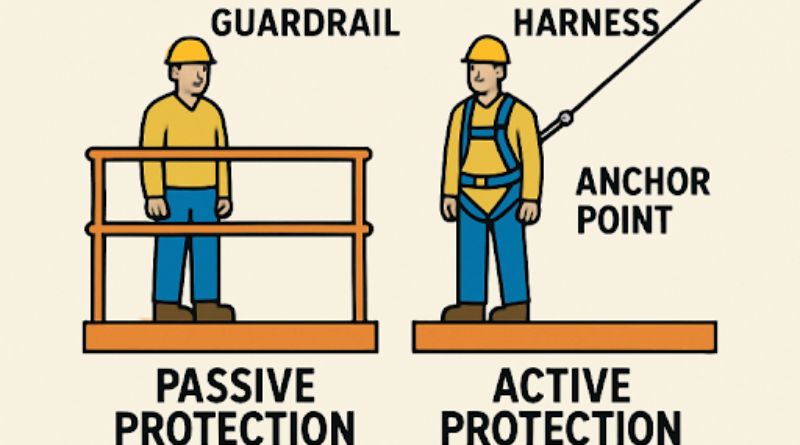

Ensuring workplace safety, especially in industries where falls are a significant risk, involves choosing the right balance of active and passive fall protection systems. Active fall protection equipment Little Rock and solutions that require worker interaction and ongoing participation. Common examples include harnesses, lanyards, lifelines, and anchors. These systems are adaptable and crucial for environments with changing work zones or when temporary access at heights is necessary.

Passive fall protection, on the other hand, relies on permanently installed barriers or structures, like guardrails and safety nets, which protect workers without requiring individual action. This approach is ideal for areas where long-term or ongoing hazard mitigation is needed, such as on leading edges or rooftops.

The Mechanics of Active Fall Protection

Active fall protection systems include full-body harnesses, self-retracting lifelines, shock-absorbing lanyards, and secure anchoring devices. The main benefit of active controls is flexibility—workers are free to move in complex or evolving environments while being secured against potential falls.

The Effectiveness of Passive Fall Protection Systems

Passive fall protection methods, like guardrails, safety nets, and floor hole covers, create a physical barrier between workers and hazards. Once in place, these systems are always “on,” reducing dependency on worker action and minimizing the chance of human error.

Key benefits include minimal need for specialized training and the ability to provide continuous protection for multiple workers simultaneously. However, initial installation costs and adapting these solutions to complex worksites can be challenging.

Cost-Benefit Considerations in Choosing a System

Deciding between active and passive fall protection systems often involves balancing initial costs against long-term safety and compliance benefits. Passive systems can be more expensive up front due to installation but typically require less ongoing maintenance and fewer replacements.

Active systems may have a lower entry cost and offer greater adaptability, but they bring higher long-term costs in the form of inspections, repairs, and recurring worker training. Initial expenditure may be a deciding factor for smaller businesses, while larger enterprises often focus on total lifecycle value and regulatory risk reduction.

Compliance, Training, and Worker Engagement

Compliance is more than simply purchasing the right gear. Continuous worker education is critical: even the best equipment can fail incorrectly. Common pitfalls include skipped inspections, improper harness fit, or misunderstanding anchor points.

Building a safety-centric culture involves leadership engagement, ongoing training, and encouraging workers to report hazards and near-misses. Frequent toolbox talks and visible management support create an environment where workers are empowered and motivated to value safety.

Integrating Active and Passive Methods for Enhanced Safety

For many scenarios, the best results come from layering active and passive protections. For example, a worker may be safeguarded by a perimeter guardrail and a personal fall arrest system when working near an open edge. This redundancy covers lapses in one system and tackles evolving site hazards.

As outlined by the National Safety Council, industry best practices recommend adopting a hierarchy of controls—starting with elimination, then passive, and finally active measures—while routinely reassessing equipment and procedures.

Final Thoughts: Finding the Right Balance for Your Worksite

Choosing the right mix of fall protection methods is crucial for safeguarding workers. Assess your hazards, evaluate worksite conditions, and invest in reliable solutions to protect your team. Review and update protection strategies regularly to reflect changing regulations, site layouts, and worker needs.

The next steps for safety managers and workers include conducting a fresh hazard assessment, ensuring all team members are trained, and scheduling regular inspections. A commitment to both active and passive methods—informed by ongoing risk analysis and regulatory updates—guarantees the greatest level of workplace safety.